Let’s Go

Dream it.

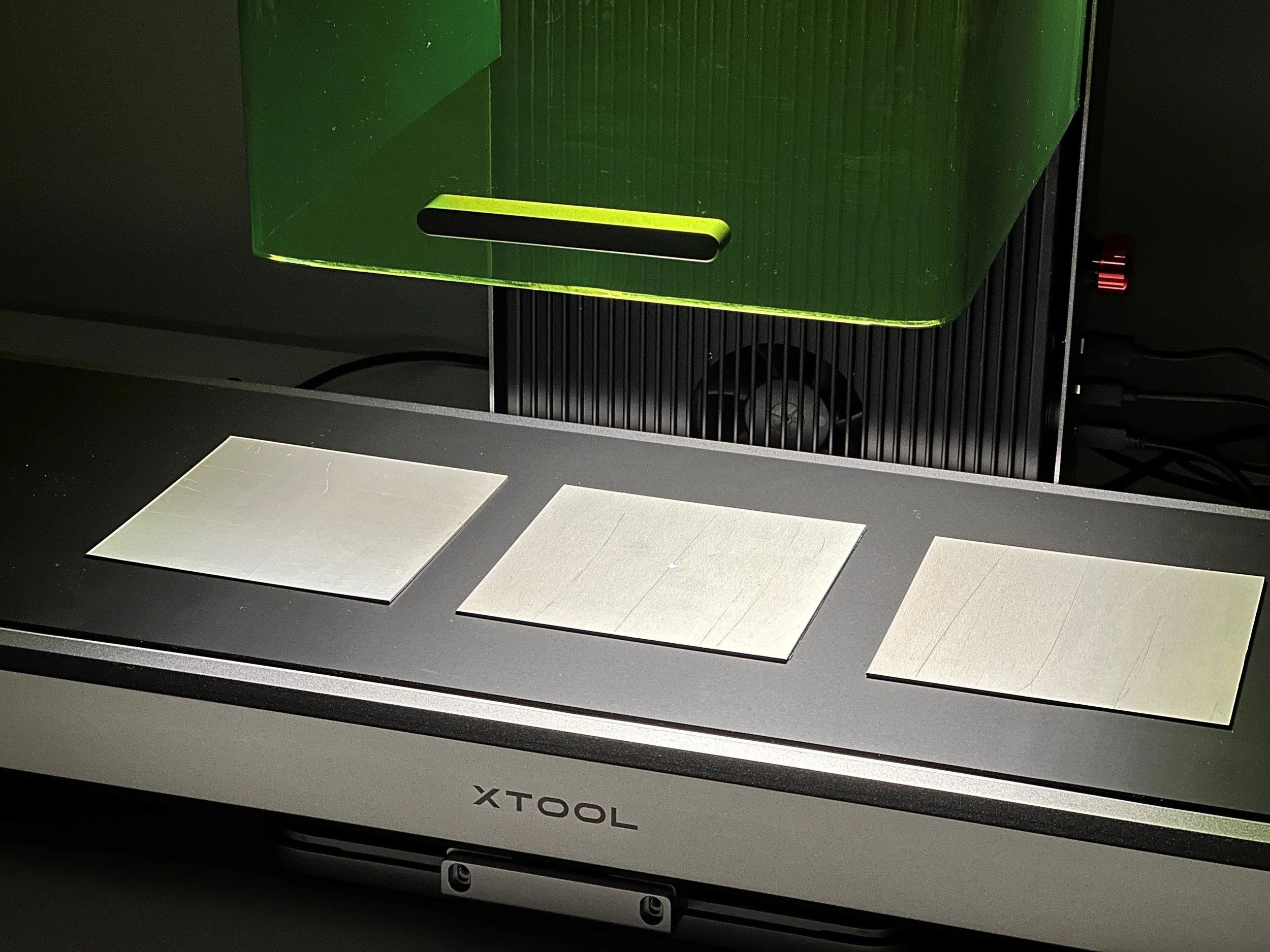

Want to make 10’s, 100’s (or even 1000’s!) of parts? Our conveyor system, combined with our laser’s 16MP camera positioning system, allows for live monitoring and tracking of parts, giving us class leading manufacturing efficiency for batch and repeat work.

The setup time is usually a major part in determining the price of engraving or cutting. However with our automated system, the setup time is drastically reduced.

Build it.

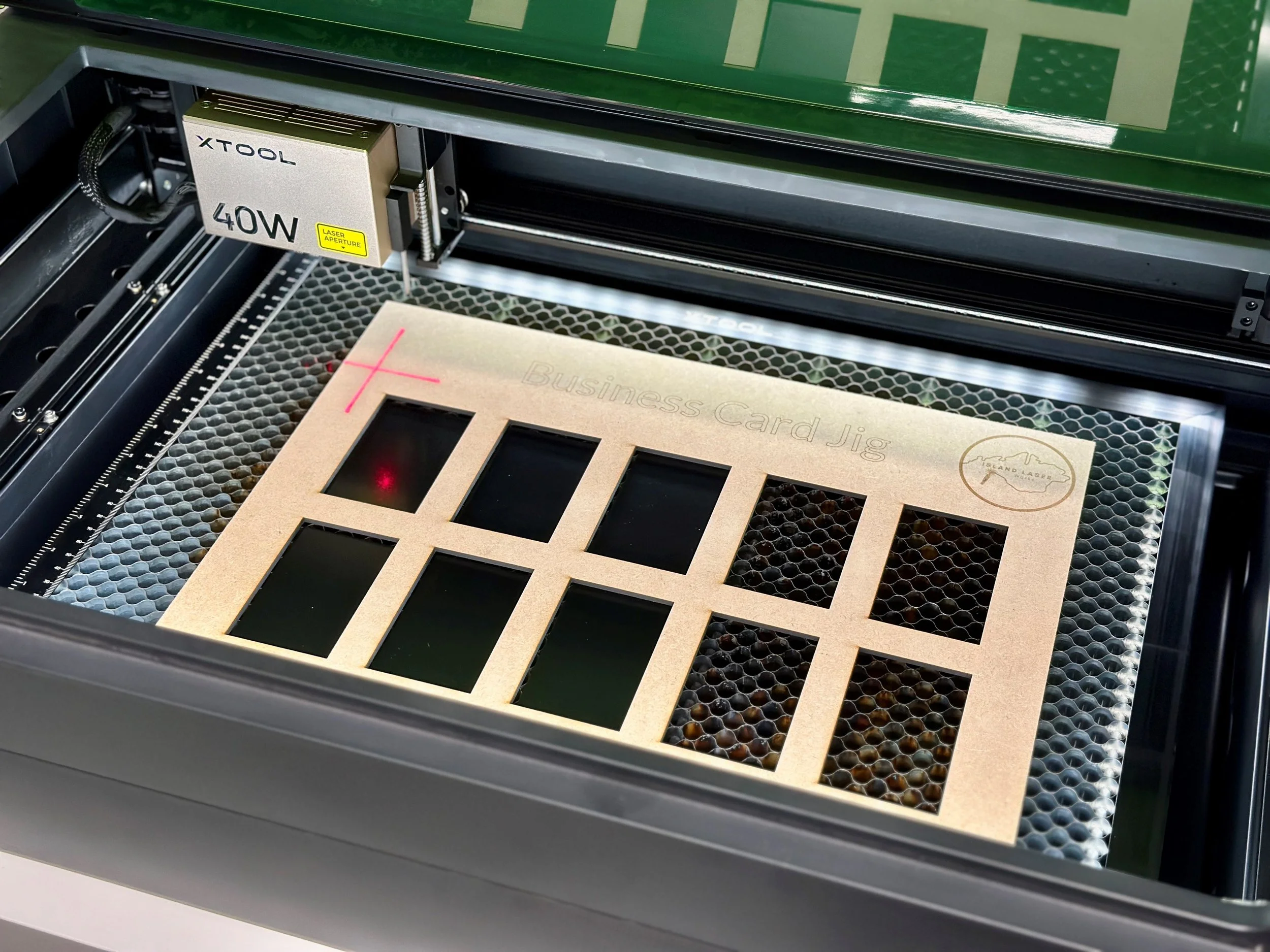

If you have complex or intricate parts which require engraving, we can design and manufacture custom jigs to act as work holding , ensuring your parts are securely held for maximum efficiency.

Jigs can be especially useful if the parts which are to be cut or engraved are extremely thin or lightweight, ensuring they stay firmly positioned and more repeatable manufacture.

Optimize it.

As well as our conveyor system on our fibre lasers, we can design templates to batch multiples of the same type (or different!) products on the same bed. This allows for one machine setup, saving considerable cost. For business cards and coin engraving, a pre-designed and manufactured template makes batch work a breeze.