Frequently Asked Questions

What Materials Do You Part Mark & Engrave?

Wood (Any soft or hard wood), Aluminium (Bare or anodised/painted), Stainless Steel, Brass, Gold, Copper, Titanium, Slate, Stone, Glass, Acrylic & Cardboard.

In summary, virtually any material! This is achieved by engraving the material at various wavelengths from Infrared to blue light which ensures the substrate can absorb the energy. We use both diode and fibre lasers.

What Materials Can You Cut?

Soft woods up to 18mm and hard woods up to 15mm thick. Acrylic sheet can also be cut depending on the colour. We cannot cut translucent Acrylic.

In terms of cutting metallics:

0.4mm thick Brass

0.3mm Stainless Steel

0.2mm Aluminium

We can also 3D emboss metallics using our state of the art Ai driven software.

What Size Can You Work To?

Our blue diode and Infrared machines have a bed size of 498mm x 319mm and can accommodate a height of up to 125mm. Our fibre lasers can engrave a maximum size of 500mm x 220mm with a height up to 145mm.

Can you engrave spherical and cylindrical objects?

The simple answer is yes! We have a rotary attachment for spherical and cylindrical objects, allowing the part to rotate whilst the laser is active. Some of the items we have engraved include:

Baseballs

Golf balls

Bolts

Watches

Wedding rings (both inside and outside surfaces)

Vases

Tumblers

Hipflasks

What Finishes Can You Offer?

Any woods can be oiled, varnished or painted depending on your requirements. Our chopping boards are oiled with a food safe grade of Danish oil. We usually wax or clear lacquer slate for a nice contrasting finish and can even use “laser sprays” to engrave dark text (or coloured) onto natural metals and alloys.

Can you help me with my design?

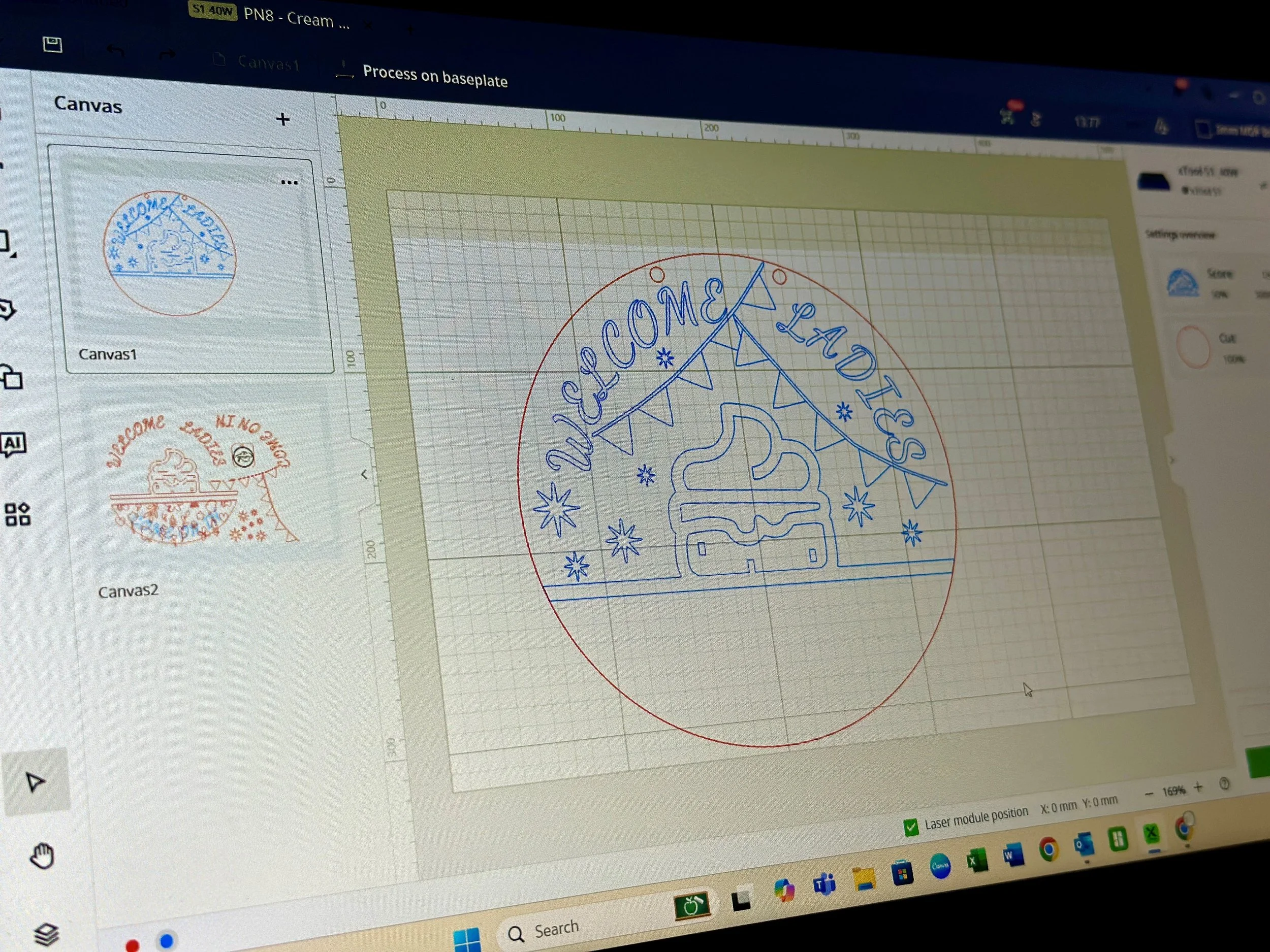

Island Laser Works uses XTool Creative Space to provide design support to our customers. Need help designing your perfect logo? No problem! Our team can turn even a simple pencil sketch into professional art work

What Makes Island Laser Works Different To Other Laser Engraving & Cutting Companies?

We use state of the art laser technology with engraving speeds up to 10,000mm/s with surface meshing for competitive pricing. Surface meshing allows us to engrave on non-planar surfaces such as vases whereby the laser can adjust its focus along the length of the object. Customer satisfaction is our top priority and we want to ensure you receive a quality item with a personalised touch.